Precision Tubes Meaning

The precision stainless steel tube is a hollow strip of steel.

A large number of pipes used to transport fluids, such as petroleum, natural gas, water, gas, steam, and the like.

In addition, when the bending and torsional strength are the same, the weight is light, so it is also widely used in the manufacture of mechanical parts and engineering structures.

Also used to produce a variety of conventional weapons, barrels, shells and so on.

Stainless steel precision tube generally refers to precision stainless steel tube

Precision stainless steel pipe is safe, reliable, environmentally friendly and economical.

The thin wall of the pipe and the successful development of a new reliable, simple and convenient connection method have the advantage that it has more irreplaceable other pipes.

There will be more and more applications in the project, and the use will become more and more popular, and the prospects are promising.

Classification

Precision stainless steel tubes are divided into two categories: seamless precision stainless steel tubes and welded precision stainless steel tubes.

According to the shape of the section, it can be divided into round precision stainless steel tubes and special-shaped precision stainless steel tubes.

Widely used in round precision stainless steel tubes, but also some square, rectangular, semi-circular, hexagonal, equilateral triangle, octagonal and other shaped steel tubes.

Stainless Steel Precision Tube Classification:

Small diameter precision stainless steel tube manufactured by JawaySteel

Product features and advantages

Small diameter precision stainless steel tube is a new environmentally friendly material.

Its main features are high precision, and the inner and outer diameter dimensions can be up to 0.2mm.

And compared with similar products, it has the same bending and torsional strength, but also has a lighter weight.

The use of small-diameter precision tubes for processing and manufacturing not only saves machining time, improves production efficiency and material utilization, but also effectively guarantees product quality, so it is used in many fields.

Specifications, materials, standards and uses

| Product name | Specifications (outer diameter x thickness) mm | Inner and outer diameter tolerance mm | Surface roughness Ra | Material | Executive standard | Scope of use |

| Small diameter precision stainless steel tube | ¢4~45×0.3~8 | ±0.05 | Ra0.8 | Carbon steel, stainless steel, bearing steel, alloy steel, chrome molybdenum steel, etc. | GB/T3639 GB/T8713 DIN2391-2 HK15-2000 |

Products are widely used in automobiles, ships, home appliances, etc. |

Shaped precision stainless steel tube manufactured by JawaySteel

Characteristics

Shaped precision stainless steel tubes generally have two or more uneven irregular bores.

Moreover, the cross section is usually disordered due to the asymmetry, so that the flow velocity distribution unevenness is likely to occur in the cross section.

In addition, the wall thickness is also uneven, and sometimes the wall thickness difference can be ten times or even tens of times, resulting in different extrusion swells and different residuals.

Unlike ordinary shaped tubes, precision shaped tubes are superior in precision and brightness, so they are favored by various industries.

Specifications, materials, standards and uses

| Product name | Specifications (outer diameter x thickness) mm | Inner and outer diameter tolerance mm | Surface roughness Ra | Material | Executive standard | Scope of use |

| Shaped precision stainless steel tubes | ¢5~80×0.3~12 | ±0.05 | Ra0.8 | Carbon steel, stainless steel, bearing steel, alloy steel, chrome molybdenum steel, etc. | GB/T3639 GB/T8713 DIN2391-2 HK15-2001 |

Widely used in some special parts such as automobiles, motorcycles, electric vehicles, home appliances, pneumatic tool components, etc. |

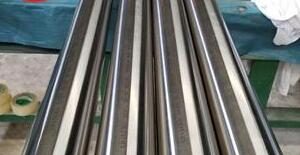

High precision seamless stainless steel tube manufactured by JawaySteel

High precision seamless stainless steel tube material

High-precision seamless stainless steel pipes can be classified into many types depending on the material of stainless steel.

The steel has 201, 304, 306, 316, 316l and other classifications. The carbon C, silicon Si, manganese Mn, sulfur S, phosphorus P, and chromium Cr contents of these steels are different.

For example, for the product 10# high-precision seamless pipe, the carbon composition is 0.07%, the silicon component is 0.17%, the manganese component is 0.35%, the sulfur component is less than 0.035%, and the phosphorus component is less than 0.035%. .

High-precision seamless tubes made of different materials have different properties and different uses.

Specifications, materials, standards and uses

| Product name | Specifications (outer diameter x thickness) mm | Inner and outer diameter tolerance mm | Surface roughness Ra | Material | Executive standard | Scope of use |

| High precision seamless stainless steel tube | ¢5~80×0.3~8 | ±0.025 | Ra0.2~0.4 | Carbon steel, stainless steel, bearing steel, alloy steel, chrome molybdenum steel, etc. | GB/T3639 GB/T8713 DIN2391-2 HK15-2000 |

Products are widely used in biological, pharmaceutical, aerospace, precision machinery and other fields with high requirements and high quality. |

Precision stainless steel seamless pipe manufactured by JawaySteel

Product features and advantages

1. Precision stainless steel seamless pipe is made by cold rolling process, so it has advantages in precision, finish and size.

2. The biggest feature of precision stainless steel seamless pipe is that it has no weld seam and has good toughness, so it has strong ability to withstand pressure.

3. The hollow section of the precision stainless steel seamless pipe has a large internal area, lighter weight and strong earthquake resistance, and can play an important role in the pipeline transportation field.

4, economic and environmental protection, non-toxic pollution, long service life, in line with the requirements of the modern sustainable scientific development concept.

Specifications, materials, standards and uses

| Product name | Specifications (outer diameter x thickness) mm | Inner and outer diameter tolerance mm | Surface roughness Ra | Material | Executive standard | Scope of use |

| Precision seamless stainless steel tube | ¢5~273×0.3~12 | ±0.05 | Ra0.8 | Carbon steel, stainless steel, bearing steel, alloy steel, chrome molybdenum steel, etc. | GB/T3639 GB/T8713 DIN2391-2 HK15-2000 |

Widely used in vehicles, home appliances, petrochemicals, electric power, ships, aerospace, bearings, pneumatic components, etc.

Also suitable for steel sleeves, bearings, hydraulics, machining, etc. |

Bright precision seamless stainless steel tube manufactured by JawaySteel

Introduction

Bright and precise seamless stainless steel tube is a widely used high precision steel tube material.

It is also a new type of environmentally friendly and energy-saving product, and is known as the “fine blood vessels in the industry”.

Usually processed by cold drawing technology or hot rolling technology.

The biggest feature is the high precision and brightness. In addition, it has the advantages of high pressure resistance, no leakage, no deformation of cold bending, and no cracking.

Therefore, it plays an important role in the fields of hydraulics, machinery, minerals, coal, automobiles, ships, aviation, and so on.

Specifications, materials, standards and uses

| Product name | Specifications (outer diameter x thickness) mm | Inner and outer diameter tolerance mm | Surface roughness Ra | Material | Executive standard | Scope of use |

| Bright precision seamless stainless steel tube | ¢5~273×0.3~12 | ±0.05 | Ra0.8 | Carbon steel, stainless steel, bearing steel, alloy steel, chrome molybdenum steel, etc. | GB/T3639 GB/T8713 DIN2391-2 HK15-2000 |

Widely used in automobiles, motorcycles, electric vehicles, home appliances, petrochemicals, electric power, ships, aerospace, bearings, pneumatic components, etc.

It can also be applied to steel sleeves, bearings, hydraulics, machining and other fields. |

Cold drawn precision stainless steel tube manufactured by JawaySteel

Usual format

The specification of Cold drawn precision stainless steel tube refers to the outer diameter and wall thickness of the pipe.

There are many specifications

Generally, the outer diameter of the tube is between 5 and 200 mm, and the wall thickness is between 2.5 and 12 mm.

Common ones are as follows:

16-17-18*2-2.5-3, 19*2-2.5-3-3.5, 21-22-23-24-25-27*2-3-4, 30-32-34-35*2- 2.5-3-3.5-4-5-6, 45-3.5-4-5-6-7-8-10-12, 52-53-55-57-58-59*2-3-4-6.

The above units are all in millimeters, and the standard can refer to GB3639-83.

Data such as nominal values and allowable deviations are also specified.

Specifications, materials, standards and uses

| Product name | Specifications (outer diameter x thickness) mm | Inner and outer diameter tolerance mm | Surface roughness Ra | Material | Executive standard | Scope of use |

| Cold drawn precision stainless steel tube | ¢8~273×0.3~16 | ±0.05 | Ra0.8 | Carbon steel, stainless steel, bearing steel, alloy steel, chrome molybdenum steel, etc. | GB/T5310-2008 GB/T6479-2000 GB/T18248-2008 GB/T8162-2008 GB/T8163-2008 |

The Cold drawn precision stainless steel tube has a hollow section and is used as a pipe for conveying fluid.

Such as pipelines for transporting oil, natural gas, gas, water and certain solid materials. Compared with solid steel such as round steel, the steel pipe has a lighter weight when it has the same bending and torsional strength, and is an economical section steel. Widely used in the manufacture of structural and mechanical parts, For example, oil drill pipes, automobile drive shafts, bicycle frames, and steel scaffolding used in construction, etc., are used to manufacture ring-shaped parts. Steel pipes have been widely used to improve material utilization, simplify manufacturing processes, and save materials and processing man-hours. |

Cold drawn precision seamless stainless steel tube manufactured by JawaySteel

Standard

There are many standards for the implementation of cold drawn precision seamless stainless steel tubes.

Generally in accordance with the provisions of GB/T8162-87.

Other common ones include GB/T 3639-2009 、 GB/T3639-1983、

GB/T 3639-2000, GB/T 3639-1983 cold-rolled or cold-drawn precision seamless steel pipe

GB/T 31315-2014 Cold-rolled or cold-drawn precision welded seamless steel pipe for mechanical structure

GB 8713-1988 precision inner diameter seamless steel pipe for hydraulic and pneumatic cylinders

GB/T 24187-2009 cold drawn precision single-layer welded steel pipe.

Specifications, materials, standards and uses

| Product name | Specifications (outer diameter x thickness) mm | Inner and outer diameter tolerance mm | Surface roughness Ra | Material | Executive standard | Scope of use |

| Cold drawn precision seamless stainless steel tube | ¢8~273×0.5~16 | ±0.05 | Ra0.8 | Carbon steel, stainless steel, bearing steel, alloy steel, chrome molybdenum steel, etc. | GB2270-80 GB/T14976-2012 GGB13296-91 GGJB2608-96 GGJB2296-95 GGB3090-82 GGB5310-2008 GGB3087-20 GGB3089-92 GGB9948-2006 |

Widely used in petroleum, chemical, medical, food, light industry, mechanical instrumentation, etc.

In addition, when the bending and torsional strength are the same, the weight is light. Therefore, it is also widely used in the manufacture of mechanical parts and engineering structures. Also used to produce a variety of conventional weapons, barrels, shells and so on. |