When we searched for seamless carbon steel pipes online, we found very little information about it. As a supplier, we feel that we need to sort out some professional introductions to help some users better understand seamless steel tubes.

Seamless Carbon Steel Pipe By JawaySteel

The seamless carbon steel pipe is formed by perforating a steel ingot or a solid tube blank, and then hot rolled, cold rolled or cold drawn.

Seamless carbon steel pipe is made of steel ingot or solid tube blank by perforation, and then made by hot rolling, cold rolling or cold drawing. Seamless carbon steel pipe plays an important role in China’s steel pipe industry.

Seamless carbon steel pipe data from China

According to incomplete statistics, there are more than 240 seamless carbon steel pipe production enterprises in China, and there are more than 250 seamless carbon steel pipe units with an annual production capacity of more than 4.5 million tons.

From the caliber, <φ76, accounting for 35%, <φ159-650, accounting for 25%.

In terms of varieties, general-purpose pipes are 1.9 million tons, accounting for 54%; oil pipes are 760,000 tons, accounting for 5.7%; hydraulic props and precision pipes are 150,000 tons, accounting for 4.3%; stainless steel pipes, bearing pipes and automobile pipes are 50,000 Tons, accounting for 1.4%.

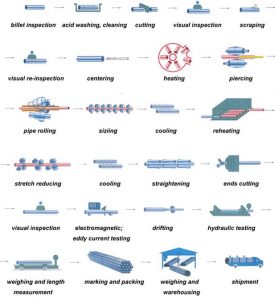

The raw material of the seamless carbon steel pipe is a round tube blank, which is cut into a blank having a length of about 1 m by a cutting machine, and sent to a furnace for heating through a conveyor belt.

The billet is fed into a furnace and heated to a temperature of approximately 1200 degrees Celsius. The fuel is hydrogen or acetylene. Furnace temperature control is a critical issue. After the round tube blank is released, it is subjected to a through-hole punching machine.

The more common perforating machine is a conical roller punching machine. This perforating machine has high production efficiency, good product quality, large diameter of perforation and can wear a variety of steel types.

After perforation, the round billet is successively rolled, rolled or extruded by three rolls. After extrusion, the tube should be sizing. The sizing machine is rotated at a high speed by a conical drill bit into a steel core to form a steel pipe.

The inner diameter of the steel pipe is determined by the outer diameter of the sizing machine drill bit. After the steel pipe has been sized, it enters the cooling tower and is cooled by water spray. After the steel pipe is cooled, it is straightened.

After the steel pipe is straightened, it is sent to a metal flaw detector (or water pressure test) by a conveyor belt for internal flaw detection. If there are cracks inside the steel pipe, bubbles and other problems will be detected.

After the quality inspection of the steel pipe, it must be carefully selected by hand. After the quality inspection of the steel pipe, the paint is sprayed with the number, specification, production batch number, etc. It is hoisted into the warehouse by a crane.

Specifications and classification

The specifications of the seamless steel pipe are expressed by the outer diameter * wall thickness in millimeters.

Classification of seamless carbon steel pipes:

Seamless steel tubes are divided into two types: hot rolled and cold rolled (dial) seamless steel tubes.

Hot-rolled seamless steel pipe are divided into general steel pipes, low and medium pressure boiler steel pipes, high pressure boiler steel pipes, alloy steel pipes, stainless steel pipes, petroleum cracking pipes, geological steel pipes and other steel pipes.

Cold-rolled (dial) seamless steel pipe in addition to general steel pipe, low and medium pressure boiler steel pipe, high pressure boiler steel pipe, alloy steel pipe, stainless steel pipe, petroleum cracking pipe, other steel pipes, also includes carbon thin-walled steel pipe, alloy thin-walled steel pipe, Stainless thin-walled steel pipe and special-shaped steel pipe.

The outer diameter of hot-rolled seamless pipe is generally larger than 32mm, the wall thickness is 2.5-75mm, the diameter of cold-rolled seamless steel pipe can reach 6mm, the wall thickness can reach 0.25mm, the outer diameter of thin-walled pipe can reach 5mm, and the wall thickness is less than 0.25mm. Cold rolling is more accurate than hot rolling.

General seamless carbon steel pipe:It is made of 10, 20, 30, 35, 45 and other high-quality carbon steel 16Mn, 5MnV and other low-alloy structural steel or 40Cr, 30CrMnSi, 45Mn2, 40MnB and other alloy steel hot-rolled or cold-rolled.

Seamless pipes made of low carbon steel such as 10 and 20 are mainly used for fluid conveying pipes.

45, 40Cr and other medium carbon steel seamless pipes are used to make mechanical parts, such as the force parts of automobiles and tractors. Generally, seamless steel pipes are required to ensure strength and flattening test.

The hot rolled steel pipe is delivered in a hot rolled state or a heat treated state; the cold rolling is delivered in a heat treated state.

Seamless steel tubes for low and medium pressure boilers:

It is used to manufacture various low and medium pressure boilers, superheated steam pipes, boiling water pipes, water wall pipes and superheated steam pipes for locomotive boilers, large smoke pipes, small smoke pipes and arch brick pipes.

Hot-rolled or cold-rolled (dial) seamless steel tubes are made of high-quality carbon structural steel. It is mainly made of steel No. 10 and No. 20. In addition to ensuring chemical composition and mechanical properties, it is required to carry out hydraulic test, crimping, flaring and flattening. Hot rolling is delivered in a hot rolled state, and cold rolled (dial) is delivered in a heat treated state.

High pressure boiler steel pipe:

It is mainly used for the manufacture of high-quality carbon structural steel, alloy structural steel and stainless steel heat-resistant steel seamless pipes for steam boiler pipes such as high pressure and above.

These boiler tubes are often operated at high temperatures and pressures, and the tubes are oxidized and corroded under the action of high temperature flue gases and water vapor.

Therefore, the steel pipe is required to have high durability, high oxidation resistance, and good structural stability.

The steel grades are: high-quality carbon structural steel with 20G, 20MnG, 25MnG; alloy structural steel No. 15MoG, 20MoG, 12CrMoG, 15CrMoG, 12Cr2MoG, 12CrMoVG, 12Cr3MoVSiTiB, etc.;

In addition to the chemical composition and mechanical properties of the 1Cr18Ni9 and 1Cr18Ni11Nb high-pressure boiler tubes for rust-resistant heat-resistant steel, the hydraulic test should be carried out one by one, and the flaring and flattening tests should be carried out. The steel pipe is delivered in a heat treated state.

In addition, there are certain requirements for the microstructure, grain size and decarburization layer of the finished steel pipe.

Seamless steel pipes for geological drilling and oil drilling:

In order to find out the conditions of underground rock formation, groundwater, oil, natural gas and mineral resources, drilling wells are used.

Oil and natural gas mining is inseparable from drilling wells. Seamless steel pipes for oil drilling for geological drilling are the main equipment for drilling, mainly including core outer tubes, core inner tubes, casings and drill pipes.

Because the drilling pipe is deep enough to work in a depth of several kilometers, the working conditions are extremely complicated, and the drill pipe is subjected to stress such as tension, pressure, bending, torsion and unbalanced impact load, and is also subject to mud and rock wear. Therefore, the pipe is required. Must have sufficient strength, hardness, wear resistance and impact toughness.

Petroleum cracking tube:

Seamless tubes for furnace tubes, heat exchanger tubes and pipes used in petroleum refineries.

It is made of high quality carbon steel (10, 20), alloy steel (12CrMo, 15CrMo), heat resistant steel (12Cr2Mo, 15Cr5Mo), stainless steel (1Cr18Ni9, 1Cr18Ni9Ti).

Seamless Carbon Steel Pipe Executive standard

1. Structural seamless steel pipe (GBT8162-2008).

Mainly used for general structural and mechanical structures. Its representative material (brand): carbon steel, 20, 45 steel; alloy steel Q345, 20Cr, 40Cr, 20CrMo, 30-35CrMo, 42CrMo and so on.

2. Seamless steel pipe for conveying fluid (GBT8163-2008).

Mainly used for conveying fluid pipelines on engineering and large equipment. The representative material (brand) is 20, Q345, etc.

3. Seamless steel pipe for low and medium pressure boilers (GB3087-2008)

Mainly used for manufacturing high-quality carbon structural steel hot-rolled and cold-drawn (rolled) for superheated steam pipes, boiling water pipes and locomotive boiler superheated steam pipes, large smoke pipes, small smoke pipes and arch brick pipes. Seamless steel tubes. The representative material is steel No. 10 and No. 20.

4. Seamless steel pipe for high pressure boiler (GB5310-2008)

It is mainly used for the manufacture of high-quality carbon steel, alloy steel and stainless steel heat-resistant steel seamless pipes for the heating surface of water tube boilers with high pressure and above. Representative materials are 20G, 12Cr1MoVG, 15CrMoG, etc.

5. Seamless steel pipe for high pressure fertilizer equipment (GB6479-2000)

It is mainly used for high-quality carbon structural steel and alloy steel seamless steel pipe for chemical equipment and pipelines with working temperature of -40~400 °C and working pressure of 10~30Ma. Representative materials are 20, 16Mn, 12CrMo, 12Cr2Mo and the like.

6. Seamless steel pipe for petroleum cracking (GB9948-2006)

Mainly used in boilers, heat exchangers and pipelines for conveying fluids in petroleum smelters. The representative materials are 20, 12CrMo, 1Cr5Mo, 1Cr19Ni11Nb and the like.

7. Steel pipe for geological drilling (YB235-70)

It is a steel pipe used for core drilling by the geological department. It can be divided into drill pipe, drill collar, core pipe, casing and sedimentation pipe according to the application.

8. Seamless steel pipe for diamond core drilling (GB3423-82)

Seamless steel pipe for drill pipe, core rod and casing mainly used for diamond core drilling.

9. Oil Drilling Pipe (YB528-65)

It is mainly used for seamless steel pipe thickened or thickened at both ends of oil drilling. There are two kinds of steel pipe and no wire, the wire pipe is connected by a joint, and the non-wire pipe is welded by a butt welding method and a tool joint.

10. Carbon steel and carbon-manganese steel seamless steel tubes for ships (GB/5312-1999)

It is a carbon steel seamless steel pipe for ship class I pressure pipe system, class II pressure pipe system, boiler and superheater. The working temperature of the carbon steel seamless steel pipe wall does not exceed 450 ° C, and the working temperature of the alloy steel seamless steel pipe wall exceeds 450 ° C. Representative materials are 360, 410, 460 steel grades, etc.

11. Seamless steel pipe for automobile semi-axle casing (GB3088-82)

It is a high-quality carbon structural steel and alloy structural steel hot-rolled seamless steel pipe for the manufacture of automobile semi-axle bushings and axles for drive axles.

12. High-pressure oil pipe for diesel engine (GB3093-86)

It is a cold drawn seamless steel pipe for the manufacture of high pressure pipes for diesel injection systems.

13. Precision inner diameter seamless steel pipe for hydraulic and pneumatic cylinders (GB8713-88)

It is a cold drawn or cold rolled precision seamless steel pipe with precision inner diameter for hydraulic and pneumatic cylinders.

14. Cold drawn or cold rolled precision seamless steel pipe (GB3639-83)

It is mainly used for cold drawn or cold rolled precision seamless steel tubes with high dimensional accuracy and good surface finish for mechanical structures and hydraulic equipment. The use of precision seamless steel tubes to manufacture mechanical structures or hydraulic equipment can greatly reduce machining time, improve material utilization, and improve product quality.

15. Stainless steel seamless steel pipe for structure (GB/T14975-2002)

It is mainly used for hot-rolled (extruded, expanded) and cold drawn (rolled) seamless steel tubes made of stainless steel for corrosion-resistant pipes and structural parts and parts of chemical, petroleum, textile, medical, food, machinery and other industries.

16. Stainless steel seamless steel pipe for fluid transportation (GB/T14976-2002)

It is mainly used for hot rolling (squeezing, expanding) and cold drawing (rolling) seamless steel tubes made of stainless steel for conveying fluids.

17. Seamless steel pipe for gas cylinders (GB18248-2000)

Mainly used to make various gas and hydraulic cylinders. The representative materials are 37Mn, 34Mn2V, 35CrMo, and the like.

In addition, there is GB/T17396-1998 (hot rolled seamless steel pipe for hydraulic props),

GB3093-1986 (high-pressure seamless steel pipe for diesel engines),

GB/T3639-1983 (cold drawn or cold rolled precision seamless steel pipe),

GB/T3094-1986 (cold drawn seamless steel pipe shaped steel pipe),

GB/T8713-1988 (precision inner diameter seamless steel pipe for hydraulic and pneumatic cylinders),

GB13296-1991 (stainless steel seamless steel tubes for boilers and heat exchangers),

GB/T14975-2002 (stainless steel seamless steel pipe for structure),

GB/T14976-2002 (stainless steel seamless steel pipe for fluid transportation)

GB/T5035-1993 (seamless steel tubes for automotive semi-axle bushings),

API SPEC5CT-1999 (Casing and Tubing Specification), etc.