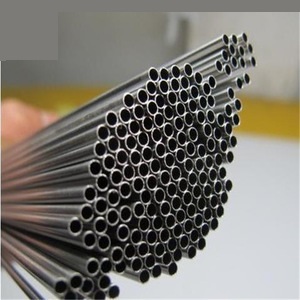

As a raw material, stainless steel capillary pipe is widely used in various fields such as chemical, petroleum, electronics, jewelry, medical, aerospace, air conditioning, medical equipment, kitchen appliances, pharmaceuticals, water supply equipment, food machinery, power generation, boilers and so on.

Specific examples are as follows:

1): medical equipment industry, injection needle, puncture needle, medical industrial tube.

2): Industrial electric heating pipe, industrial oil pipe

3): temperature sensor tube, sensor tube, grill tube, thermometer tube, thermostat tube, instrument tube, thermometer stainless steel tube.

4): Pen industry pen tube, core tube, pen tube.

5): various electronic micro tubes, fiber optic accessories, optical mixers, small diameter stainless steel capillaries 6): watch industry, child-mother, raw ear, watch with accessories, jewelry punch pin

7): Various antenna tubes, automobile tail antenna tubes, rod antenna tubes, stretching pointers, mobile phone stretching antenna tubes, miniature antenna tubes, laptop antennas, stainless steel antennas.

8): Stainless steel tube for laser engraving equipment.

9): Fish tube, fish rod tube

10): Tubes for various food and beverage industries, tubes for conveying.

Features:

It has good softness, corrosion resistance, high temperature resistance, abrasion resistance, tensile strength, water resistance and excellent electromagnetic shielding performance.

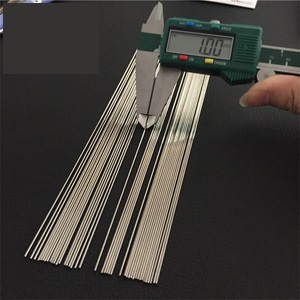

Specification:

∮2-∮8

Wall thickness:

0.1-2.0mm

Material:

SUS2507,316L, 316, 321, 310, 310S, 304, 304L, 302, 301, 202, 201, etc.

Let’s focus on the 304/310S/316/2507 stainless steel capillary pipe

304 stainless steel capillary pipe

304 stainless steel capillary pipe refers to a high-alloy steel which can resist corrosion in air or chemically corrosive medium. It has beautiful surface and good corrosion resistance. It does not need to be surface treated by plating, but exerts the surface properties inherent in stainless steel. A type of steel used in many ways.

Performance

From the perspective of metallography, because stainless steel contains chromium and the surface forms a very thin chromium film, this film is isolated from the intrusion of oxygen in the steel to resist corrosion.

In order to maintain the corrosion resistance inherent in stainless steel, steel must contain more than 12% chromium.

304 is a versatile stainless steel that is widely used to make equipment and parts that require good overall performance (corrosion resistance and formability). 304 stainless steel is a grade of stainless steel produced in accordance with American ASTM standards.

Applicable to automatic instrument signal tube, automatic instrument wire protection tube;

Precision optical ruler line, industrial sensor, electronic equipment line protection tube;

Safety protection of electrical lines, protection of thermal instrumentation capillary tubes and internal support of air-core high-voltage cables.

Chemical composition

(%)

310S stainless steel capillary pipe

When cooling, the function of the 310S stainless steel capillary is to discharge the high-pressure liquid refrigerant from the condenser into a low-pressure liquid refrigerant by throttling and then enter the evaporator.

Chemical composition

Chemical composition of 310S (%):

Ni: 19.00-22.00

Cr : 24.00-26.00

Si : <= 1.50

Mn: <= 2.00

C : <= 0.08

S : <= 0.030

P : <= 0.035

310s is austenitic chrome-nickel stainless steel with good oxidation resistance and corrosion resistance.

Because of the higher percentage of chromium and nickel, 310s has much better creep strength, can continue to work at high temperatures, and has good high temperature resistance.

Density

8.0 g / cm 3

Mechanical properties

Mechanical properties after solution treatment:

Yield strength ≥ 205, tensile strength ≥ 520, elongation ≥ 40, hardness test: HBS ≤ 187, HRB ≤ 90, HV ≤ 200

316 stainless steel capillary pipe

316 stainless steel, 18Cr-12Ni-2.5Mo stainless steel, because of the addition of Mo, it is particularly good in corrosion resistance, atmospheric corrosion resistance and high temperature strength, can be used under harsh conditions; excellent work hardening (non-magnetic).

Chemical composition

|

C

|

Si

|

Mn

|

P

|

S

|

Ni

|

Cr

|

Mo

|

|

≤0.08

|

≤1.00

|

≤2.00

|

≤0.035

|

≤0.03

|

10.0-14.0

|

16.0-18.5

|

2.0-3.0

|

Mechanical properties

|

Mpa/tensile strength

|

Mpa/Yield Strength

|

Elongation/%

|

Area reduction/%

|

Density/ρ

|

|

620 MIN

|

310 MIN

|

30 MIN

|

40 MIN

|

8.03 g/cm3

|

Characteristic

316 stainless steel capillary tube has good flexibility, corrosion resistance, high temperature resistance, abrasion resistance, tensile strength, water resistance and excellent electromagnetic shielding performance due to its small diameter. It can be bent freely into various angles and curvatures. radius,

It has the same softness and durability in all directions; the axial tensile force can withstand more than 6 times the nominal inner diameter.

2507 stainless steel capillary pipe

The 2507 duplex stainless steel capillary combines the most beneficial properties of many ferritic and austenitic steels. Due to its high chromium and molybdenum content, it has excellent resistance to pitting, crevice corrosion and uniform corrosion.

The two-way microstructure ensures that the steel has a high resistance to stress corrosion cracking and high mechanical strength.

Chemical Composition

| Element | Type |

|---|---|

| Carbon | 0.03 max. |

| Manganese | 1.2 max. |

| Sulfur | 0.020 max. |

| Phosphorus | 0.035 max. |

| Silicon | 0.80 max. |

| Chromium | 24.00 – 26.00 |

| Nickel | 6.00 – 8.00 |

| Nitrogen | 0.24 – 0.32 |

| Molybdenum | 3.00 – 5.00 |

Mechanical Property

| Type | Yield Strength

(Mpa) |

Tensile Strength (Mpa) | Elongation

(%) |

Hardness Rockwell |

|---|---|---|---|---|

| 2507 Ann (typical) | 800 – 1000 | 550 min. | 40 min. | HV290 |

Use

Mainly used in the oil and gas industry;

Offshore stone breaking oil platform (heat exchanger tube, water treatment and water supply system, fire protection system, water spray system, water stabilization system; petrochemical equipment;

Desalination (desalination) equipment (and high pressure pipes in the equipment, seawater pipes);

Combustion (waste) gas purification equipment.

Mechanical and structural components that require both high strength and high corrosion resistance;

Capillary as a raw material is widely used in chemical, petroleum, electronics, jewelry, medical, aerospace, air conditioning, medical equipment, kitchen appliances, pharmaceuticals, water supply equipment, food machinery, power generation, boilers and other fields.