Customers who often deal with stainless steel should understand the following words: no stainless steel without chromium, no stainless steel without nickel.

The role of nickel in stainless steel has been an important factor in corrosion protection, and today we will talk about the role of chromium in stainless steel.

Concept:

It is said that chromium plays a decisive role in stainless steel.

Chromium is a basic alloying element in stainless steel, and its content is generally above 13%.

Both the 200 stainless steel series and the 300-series stainless steel, which has a major market share, contain both elements. The reason is simple, and chromium has an effect on steel structure.

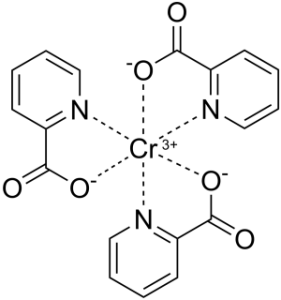

Chromium is a carbide forming element. In the metal material, it can form a metal compound such as Cr3C with carbon, and the metal compound has high strength and hardness. When it is dispersed in a granular form on a metal substrate, the strength, toughness and wear resistance of the material can be greatly improved.

Significance:

Each stainless steel contains a certain amount of chromium. To date, there is no stainless steel that does not contain chromium. The reason why chromium has become the main element determining the performance of stainless steel is that after adding chromium as an alloying element to steel, it promotes the contradictory movement inside it to the development of corrosion resistance.

This magical coordination function change can be explained from the following aspects:

Chromium hinders austenite grain growth In addition to manganese, all alloying elements can hinder the growth of austenite grains during heating.

In the material, the presence of the carbide Cr3C formed with carbon, when the heating temperature is not too high, the undissolved carbide can hinder the growth of austenite grains.

This makes it easy to obtain fine austenite grains, thereby obtaining a fine cooled structure. We know that fine grains have higher strength, better plasticity and toughness than coarse grains.

Chromium can improve the hardenability of the material after quenching, which reduces the small cooling rate of the martensite structure, and the martensite structure is more easily obtained, thereby reducing the content of retained austenite.

More tempering tissue is obtained during tempering, and the excellent performance of this tempering structure is what we need.

The role of chromium in stainless steel:

The role of stainless steel chromium in stainless steel is mainly to improve the corrosion resistance of steel.

In oxidizing media, there is an oxide that forms a strong and dense chromium on the steel surface to protect the steel.

Chromium can also be combined with nickel to form a single-phase austenite structure and impart good corrosion resistance, good toughness and strength to the steel.

It can be seen that the role of chromium in stainless steel is particularly important. Properly applying chromium to various materials can improve the performance of the material.